Accelerators use a huge amount of electrical energy, both to create high-energy beams and to steer and focus those beams. In the vast majority of cases, the steering and focusing is carried out by electromagnets. If they were replaced by permanent magnets (PM), this electrical energy demand could be reduced to zero, vastly reducing the carbon footprint of accelerator systems. However, permanent magnets are based on rare-earth elements (typically neodymium or samarium). The carbon cost of extracting and processing the raw materials for rare-earth magnets is not usually taken into account when considering whether to use electromagnets or permanent magnets, and so it’s not always obvious if this is a truly ‘green’ technology.

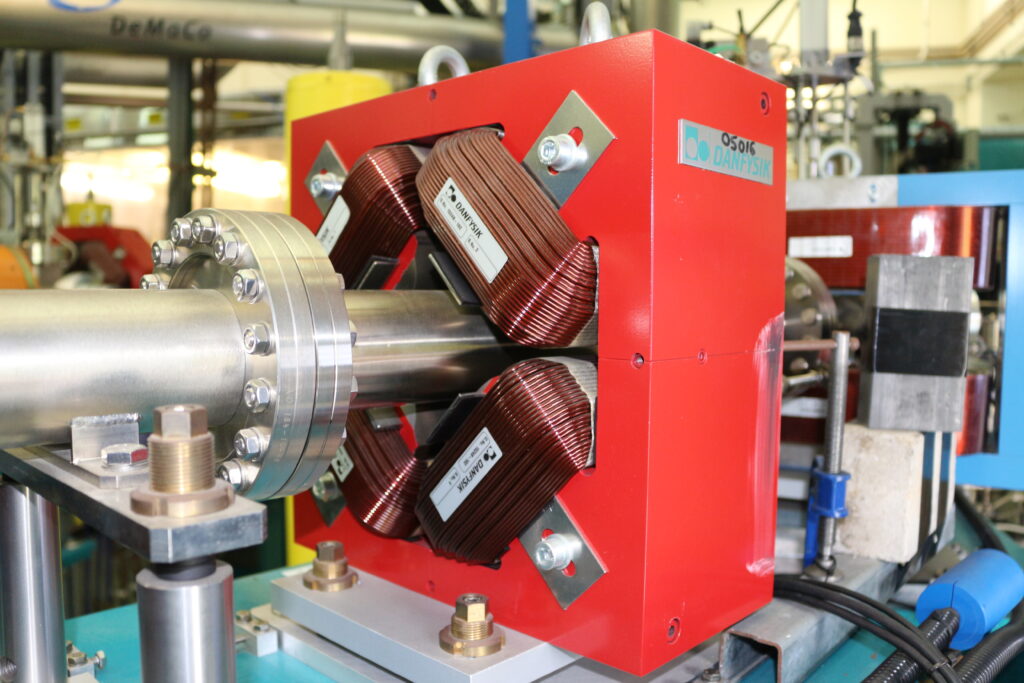

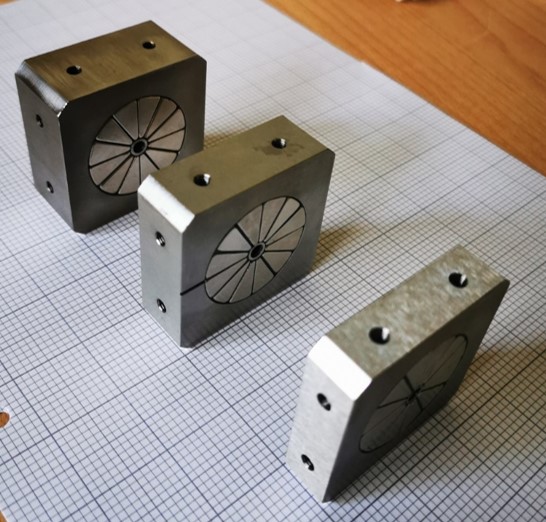

CI expert Ben Shepherd (STFC/ASTeC) recently attended a workshop at DESY focussing on the climate impacts of rare-earth materials. He carried out a study looking at recent examples of magnets used on STFC’s CLARA accelerator. The three electromagnets studied are all quadrupoles and could all (in principle) be replaced by fixed-field permanent magnet devices known as Halbach quadrupoles. The Halbach devices consist of PM wedges arranged around the beam aperture and are considerably more compact than the equivalent electromagnets.

For a comparison of the carbon footprints, we can find figures in the scientific literature for carbon impacts of the various materials used in manufacture – in other words, how much CO₂ is produced for each kilogram of material. These figures vary from country to country, depending on the technologies used for extraction and processing – for instance, some countries have switched to electric arc furnaces to produce steel, which is usually a greener option than traditional coke-fired blast furnaces (depending on the local electricity production mix). Figures for the carbon impact of permanent magnets are more variable and harder to pin down; most PMs are produced in China and data can be difficult to verify. However, there is agreement that the carbon impact of PM materials is far greater than that of more commonly-used materials like copper and steel.

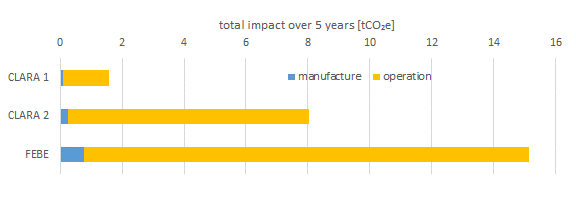

The bottom line is that the climate impact of building an electromagnet is broadly similar to that of building the equivalent fixed-field Halbach magnet. However, the impact of operating an electromagnet is significant: they typically draw 1-2kW of electrical power, corresponding to several tonnes of CO₂ produced over a year of continuous operation. They must also be water-cooled, which can add extra power consumption on top. A PM-based device needs no electrical power and no cooling, and thus its operational carbon footprint is zero.

In conclusion, over the lifetime of an accelerator, permanent magnet systems have a vastly lower carbon footprint than traditional electromagnet systems, even when we take into account the high cost of extracting and processing the raw materials.